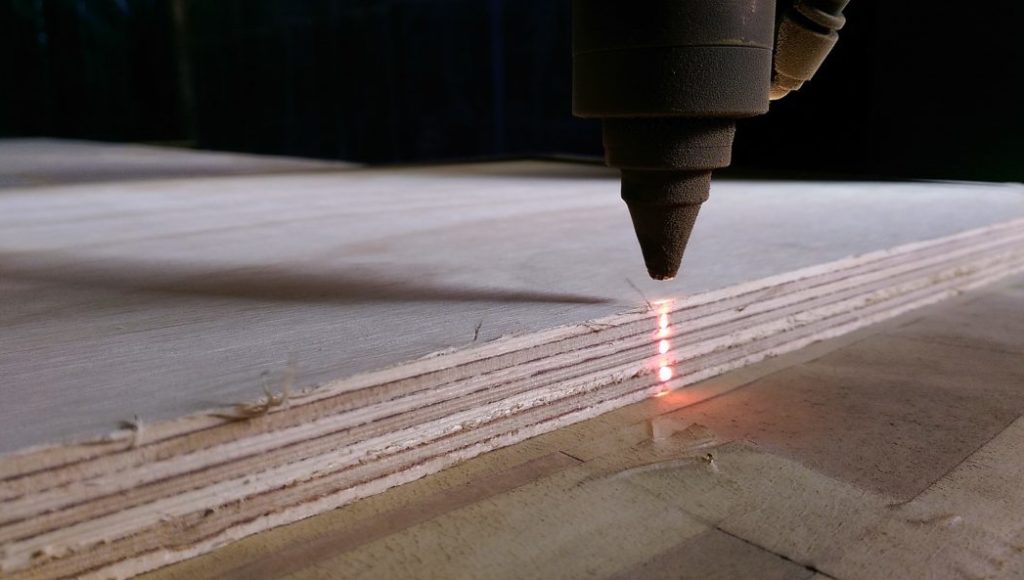

Looking for a production run of material, but don’t want to deal with a large manufacturing company? We can help you produce small to large production runs of various CNC and fabrication work – in any shape in wood, foam, MDF, acrylic and metal.

Our team is focused on quality and rapid turn-around of projects.

With our CNC Router, we can cut on 4-axes, allowing us to do production runs of round and three-dimensional shapes.

With our CNC Laser machine, we can quickly cut multiple images and shapes in many different types of materials, scaled in small or large format .